ACL has saved over 78 million dollars in louver maintenance costs

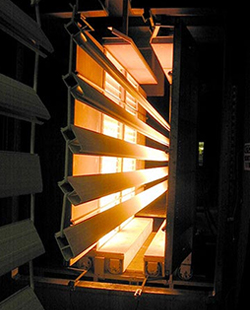

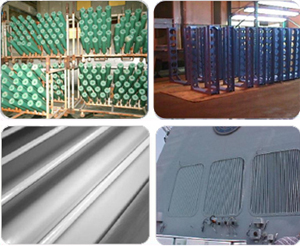

Proven track record with the U.S. Navy air intake and uptake louvers dual immersion polymer powder process.

An extremely durable fusion bonded multilayer process designed to encapsulate the component, uniformly covering inaccessible areas where all other coatings fail.

- 14 year track record on Louvers

- 5 -year limited warranty

- Coating life cycle of 9 to 15 years

ACL’s Capabilities

- The most technologically advanced powder and liquid coating facility in North America

- Approved and certified for pipe coating, tank lining, architectural aluminum, fluid bed and electrostatic applications

- Architectural aluminum approved, AAMA 2603, 04, 05

- 35-ton crane capacity

- Extensive coating testing lab

- Mobile blast and coating services

- Multiple wheelabrators, airblastrooms and chemical pretreatment

- 70,000 square foot facility

- U.S. Military approved

- Plural component 100% solids liquid epoxies

- Onsite engineering/CAD/Solidworks

- Thermal Arc Spray Metalizing

- Robotic powder applicators ensuring repeatable quality

Automatic Coating Limited is your Authorized Patch Kit supplier

ACL makes using your tidal coat patch kits easy to use, no weighing or measuring, quick to apply and eliminates waste. ACL can help you discover how this efficient product can help you and your company save time and maximize productivity.

Click here to learn how to repair your louvers

Back