Introduction to ACL

ACL stands at the forefront of powder coating technology in Toronto, specializing in custom solutions that cater to a diverse range of industries. With a commitment to excellence and a robust portfolio that includes architectural aluminum, corrosion protection, and decorative finishes, ACL has established itself as a leader in the field. Whether you need small components like pens or large structures such as 10,000-pound pipes, ACL is equipped to deliver high-quality coatings that can withstand the most hostile environments, including underwater, mining, and paper mill applications.

Benefits of Powder Coating

Powder coating offers numerous advantages over traditional liquid coatings. One of the most significant benefits is its durability. The powder coating finish is resistant to chemicals, humidity, inclement weather, and abrasion, making it ideal for components that face harsh conditions. By significantly reducing wear and tear, powder coating not only enhances the aesthetic appeal of the parts but also lowers maintenance costs and extends the overall lifecycle of the coated items. This reliability makes ACL’s services a wise investment for any business looking to protect its assets.

Comprehensive Coating Services

ACL’s coating capabilities include both single and multi-coat electrostatic powder coating and fluid bed coating services. This flexibility allows them to meet a wide range of customer requirements, ensuring that every project is executed with precision and care. As an approved source for military and automotive coatings, ACL’s reputation for quality is recognized across multiple sectors.

Distinctive Features of ACL

What sets ACL apart from its competitors is its commitment to quality through three key areas: state-of-the-art equipment, world-class pretreatment, and superior processes that yield a higher quality finish and longer-lasting results.

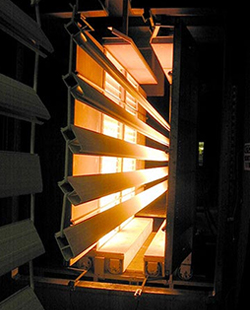

1. State-of-the-Art Powder Coating Equipment

ACL has made substantial investments in cutting-edge powder coating equipment, ensuring that their clients receive top-notch finished products at competitive prices. Their conveyor coating lines can accommodate items up to 35 feet long, 8 feet high, and 4 feet wide, making it possible to handle medium to large batch sizes efficiently. For smaller projects, ACL employs several batch systems, allowing for customized solutions tailored to specific needs. Furthermore, their high-quality spray booths are designed to ensure that each custom job meets the highest standards of craftsmanship and longevity.

2. Advanced Powder Coating Methodologies

Electrostatic Process

ACL utilizes the latest in electrostatic powder coating technology, featuring automatic ITWGema PLC-controlled equipment. This advanced system is equipped with parts scanning capabilities and rapid color change functionality, allowing for consistent and high-quality results. The technology enhances flexibility in coating applications and improves turnaround times, enabling ACL to manage a variety of projects efficiently.

Fluid Bed Process

In addition to electrostatic techniques, ACL is a pioneer in fluid bed coating, having provided these services since the 1960s. Their fluid bed dip systems are among the most advanced in the industry, designed to ensure accurate and repeatable results. This long-standing expertise means that ACL can meet the specific requirements of customers while delivering consistent, high-quality powder coating services. Furthermore, ACL offers custom-designed equipment solutions for clients wishing to implement their own coating processes.

3. Superior Pretreatment

Pretreatment is crucial for the longevity and effectiveness of any coating application. ACL employs a variety of methods to prepare metal substrates, enhancing bond strength and ensuring lasting protection. Their capabilities include aluminum conversion coating, five-stage iron and zinc phosphate processes, grit blasting, steam cleaning, chemical etching, and phosphatizing. An innovative automated wheelabrator system allows ACL to blast pipes efficiently for various industries, ensuring that all surfaces are primed for optimal coating adhesion. The skilled project managers at ACL meticulously determine the best pretreatment procedures for each project, contributing to the overall success of the coating process.

Commitment to Quality and Customer Satisfaction

At ACL, quality is not just a promise; it’s a fundamental aspect of their operation. Each project is approached with meticulous attention to detail, ensuring that the final product meets or exceeds customer expectations. Their extensive experience and state-of-the-art facilities allow them to tackle even the most challenging coating tasks with confidence.

Conclusion

ACL Powder Coating Solutions is more than just a coating service; it’s a comprehensive resource for businesses in Toronto seeking high-quality, durable coatings. With a commitment to innovation and customer satisfaction, ACL’s expertise in powder coating, combined with their advanced equipment and methodologies, makes them the go-to provider for all coating needs. Whether you are looking for protective finishes for industrial applications or decorative coatings for architectural projects, ACL is your trusted partner in delivering exceptional results that stand the test of time.

Back