In the realm of industrial applications, the integrity and durability of pipes are critical for operational efficiency and safety. Coating is an essential process that enhances the performance of pipes, especially in demanding environments. This article will delve into the various aspects of internal and external pipe coating, focusing on applications for pipes ranging from small bore to 8 feet in diameter, and highlighting the expertise of Automatic Coating Limited (ACL) in this specialized field.

Importance of Pipe Coating

Pipes are subjected to harsh conditions, including extreme temperatures, corrosive substances, and mechanical wear. Coatings serve as protective barriers that prevent corrosion, abrasion, and other forms of deterioration. The selection of an appropriate coating system is crucial, particularly for pipelines used in transporting oil, gas, and other hazardous materials.

Internal Pipe Coating

Internal coatings are designed to protect the inner surfaces of pipes from corrosive fluids and improve the flow characteristics. This is especially important in pipelines that transport crude oil, natural gas, or water, where the presence of corrosive elements can lead to significant maintenance costs and operational downtime.

ACL specializes in high solids and 100% solid epoxy coatings that provide excellent adhesion and resistance to a variety of chemicals. These coatings are formulated to withstand high pressures and temperatures, making them suitable for various industrial applications.

External Pipe Coating

External coatings protect the outer surfaces of pipes from environmental factors, including moisture, UV radiation, and physical abrasion. This is vital for ensuring the longevity of pipelines, particularly those installed above ground or in exposed locations.

ACL has established itself as a leader in external pipe coating, employing advanced techniques to ensure a uniform and durable finish. Their capabilities extend to pipes with diameters up to 8 feet, meeting the rigorous standards set by major companies in the industry.

Approved Coater for Major Pipelines

Automatic Coating Limited is an approved coater for renowned companies such as Enbridge, TransCanada, and Spectra Energy. This approval reflects ACL’s commitment to quality and adherence to strict industry standards. The company has successfully completed high-profile projects, including the Keystone Pipeline and SNC Lavalin Potash mines, demonstrating their expertise in handling large-scale coating operations.

ACL’s reputation extends beyond North America, having also worked on significant international projects such as the Middle East sulphur extraction project and NHL ice refrigeration systems. These diverse projects showcase the company’s versatility and ability to meet various coating specifications.

Advanced Coating Technology

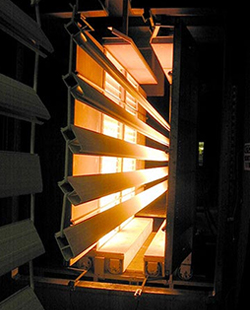

ACL utilizes state-of-the-art liquid coating equipment and plural component rigs that enable the application of a wide variety of coating systems. This advanced technology ensures efficiency and consistency in the coating process, allowing for the precise application of complex coatings.

The trained and approved applicators at ACL are well-versed in using products from leading manufacturers, including Carboline, Amercoat, PPG, SPC, 3M, Denso, and Akzo Nobel. This extensive knowledge of different materials and systems ensures that each project is completed to the highest standards, tailored to the specific needs of the client.

Tank Lining Solutions

In addition to pipe coating, ACL offers tank lining services for both internal and external applications. Tanks used in the storage of chemicals, oil, or other hazardous materials require specialized coatings to prevent leaks and maintain structural integrity. ACL’s expertise in high solids and 100% solid epoxy systems ensures that tank linings provide optimal protection against corrosion and wear.

Wind Turbine Coating

Another area where ACL has made significant strides is in the coating of wind turbines. With the growing focus on renewable energy, the demand for effective protective coatings for wind turbine components has increased. ACL’s experience in applying durable coatings to these structures ensures that they can withstand harsh environmental conditions, extending their operational lifespan and reducing maintenance costs.

Conclusion

Automatic Coating Limited stands out as a premier liquid coater in North America, recognized for its exceptional service and high-quality coatings. From internal and external pipe coating to tank linings and wind turbine applications, ACL demonstrates a commitment to innovation and excellence in the coatings industry. Their ability to handle large-scale projects, combined with advanced technology and skilled personnel, positions them as a leader in protective coating solutions. As industries continue to evolve and demand higher standards, ACL remains at the forefront, ensuring that their clients receive the best in quality and performance.

In a world where reliability and durability are paramount, investing in quality coating solutions from a trusted provider like Automatic Coating Limited can lead to significant long-term benefits. Whether for pipelines, tanks, or renewable energy applications, the right coating can make all the difference in operational efficiency and safety.

Back