In the vibrant industrial landscape of Toronto, ACL stands out as a premier provider of pretreatment and finishing solutions. With a commitment to innovation and sustainability, ACL offers a wide array of products and services designed to meet the specific needs of various industries, including aerospace, automotive, and marine. This article will delve into ACL’s pretreatment offerings, custom machinery solutions, and finishing products, highlighting the company’s dedication to quality and environmental stewardship.

Pretreatment Solutions

ACL’s pretreatment category features an extensive range of grit blasting and sand blasting machines, as well as advanced chemical washers. These machines are crucial for preparing surfaces for coating applications, ensuring that every project meets stringent quality standards.

Grit and Sand Blasting Machines: Grit blasting involves propelling abrasive materials against surfaces to remove contaminants and create a rough texture that enhances coating adhesion. ACL’s grit and sand blasting machines are designed for efficiency and effectiveness, providing superior surface preparation. Whether dealing with metal, plastic, or other materials, these machines ensure a clean and consistent finish.

Chemical Washers: In addition to mechanical blasting, ACL offers chemical washers that employ eco-friendly cleaning agents to remove oils, greases, and other residues from surfaces. These washers are particularly beneficial for delicate materials that cannot withstand abrasive blasting. By integrating chemical cleaning into their pretreatment solutions, ACL supports businesses in achieving cleaner surfaces without compromising material integrity.

Customized Machinery for Tidal Coat Fluid Bed Dipping

One of ACL’s standout offerings is its custom machinery for Tidal Coat fluid bed dipping and field coating services. This innovative technology is particularly useful for projects requiring rapid application and high-quality finishes.

Water Tight Door Coating Machinery: A notable achievement in ACL’s portfolio is the development of specialized coating machinery for water tight doors, created for the San Diego Naval Maintenance Centre. This custom solution can automatically coat a water tight door in just two minutes, achieving first-pass quality that minimizes the need for rework. Such efficiency not only saves time but also enhances productivity in military and maritime operations where reliability is paramount.

Environmentally Friendly Solutions: Furthermore, ACL has pioneered environmentally friendly automated coating and blasting equipment specifically for pipeline rehabilitation. Traditional field coating methods can be resource-intensive and environmentally detrimental. However, ACL’s customized field coating equipment has successfully reduced greenhouse gas emissions by two-thirds compared to conventional systems. This commitment to sustainability not only aligns with global environmental goals but also mitigates the impact on local ecosystems during field operations.

Finishing Products

In addition to its robust pretreatment and custom machinery offerings, ACL provides an impressive lineup of finishing products designed to enhance the performance and appearance of coated surfaces. These products include:

Dust Collectors: Effective dust collection is critical in any coating operation to maintain a clean working environment and ensure high-quality finishes. ACL’s dust collectors are engineered to capture particulate matter, ensuring compliance with health and safety regulations while enhancing overall air quality in industrial settings.

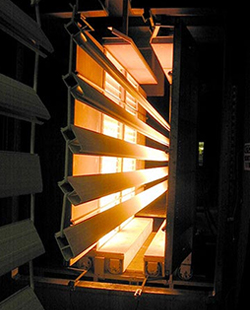

Ovens: Proper curing is essential for achieving durable coatings. ACL offers a variety of ovens that are designed for different applications, ensuring optimal temperature control and airflow for efficient drying and curing processes. Whether for powder coating, liquid coatings, or other finishing methods, ACL’s ovens deliver consistent results that meet the demands of various industries.

Spray Booths: Spray booths are crucial for controlled coating applications, minimizing overspray and ensuring even coverage. ACL’s spray booths are customizable to fit specific operational needs, providing a safe and efficient environment for applying coatings. They are designed to enhance airflow and filtration, which are essential for maintaining high standards of quality in the finishing process.

Electrostatic Finishing Powder Spray Guns: For companies looking to streamline their powder coating processes, ACL offers state-of-the-art electrostatic finishing powder spray guns. These guns utilize electrostatic technology to ensure even powder distribution, maximizing coating efficiency and minimizing waste. This technology not only improves the quality of the finish but also contributes to more sustainable practices by reducing overspray and material usage.

A Partner in Innovation

At ACL, the focus is not just on providing equipment but also on creating partnerships that foster innovation. By collaborating closely with clients, ACL can design and manufacture specialized coating equipment that meets unique operational challenges. This customer-centric approach ensures that every solution is tailored to enhance productivity while maintaining the highest quality standards.

Commitment to Quality and Sustainability

ACL’s reputation in the industry is built on a foundation of quality and sustainability. By continually investing in research and development, the company stays ahead of industry trends and regulations, ensuring that its products not only meet but exceed customer expectations. The commitment to environmentally friendly practices is evident in the design and functionality of ACL’s machinery, making it a preferred choice for businesses that prioritize sustainability in their operations.

ACL’s extensive range of pretreatment and finishing solutions positions it as a leader in the Toronto industrial landscape. From grit blasting and chemical washers to customized coating machinery and innovative finishing products, ACL provides comprehensive solutions that cater to a diverse array of industries. With a focus on quality, efficiency, and sustainability, ACL is well-equipped to support businesses in achieving their coating goals while promoting environmentally responsible practices. Let Automatic Coating be your trusted partner in designing and manufacturing specialized coating equipment that meets the demands of today’s dynamic market.

Back