In recent years, the global emphasis on renewable energy has accelerated the development and deployment of wind turbines. As these towering structures harness the wind’s kinetic energy to generate electricity, their durability and efficiency become paramount. One crucial aspect of this durability is the coating used to protect the turbines from environmental factors. This article explores the industrial applications of wind turbine coatings, focusing on ACL, a leader in coating technologies, and the advanced capabilities it brings to the industry.

The Importance of Wind Turbine Coatings

Wind turbines face harsh environmental conditions, including extreme temperatures, high winds, and corrosive elements like saltwater in coastal areas. To ensure long-term performance and safety, wind turbine components—such as the tower, blades, and nacelle—require specialized coatings. These coatings serve multiple purposes:

- Corrosion Resistance: Wind turbines are often made of steel, which can corrode over time. Protective coatings create a barrier that prevents moisture and salts from penetrating the metal.

- UV Protection: Exposure to sunlight can degrade materials, particularly those used in the turbine blades. UV-resistant coatings help maintain the structural integrity and efficiency of the blades.

- Aesthetic Appeal: Wind farms can have a visual impact on the landscape. High-quality coatings can enhance the appearance of turbines, making them more appealing.

- Maintenance Reduction: Coatings that are more durable lead to less frequent maintenance and repair needs, ultimately reducing operational costs.

- Environmental Protection: Eco-friendly coatings can minimize environmental impact, aligning with the renewable energy sector’s sustainability goals.

ACL: A Leader in Wind Turbine Coatings

ACL (Advanced Coating Laboratory) stands out as a frontrunner in providing advanced coating solutions for wind turbines. Located in North America, with a facility in Toronto, ACL is renowned for its technologically advanced powder and liquid coating options. The company’s certifications from industry leaders such as Amercoat, International Paints, SPC, Carboline, Akzo Nobel, 3M, and Denso highlight its commitment to quality and innovation.

ACL’s expertise extends beyond mere application; the company provides comprehensive onsite engineering services, including Computer-Aided Design (CAD) and SolidWorks capabilities. This integrated approach ensures that coatings are tailored to the specific needs of each wind turbine project, accommodating various sizes and complexities.

Advanced Coating Techniques

ACL employs a range of advanced coating techniques to meet the demands of the wind energy sector:

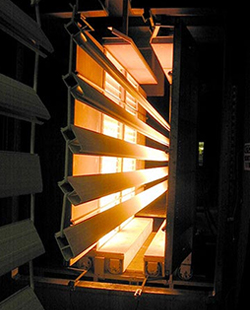

- Powder Coating: This method involves applying a dry powder to the turbine components, which is then cured under heat to form a durable layer. Powder coatings are known for their toughness, resistance to chipping, and environmental friendliness.

- Liquid Coating: Liquid coatings are applied in a manner similar to traditional paint but are formulated for superior performance. These coatings can be customized for specific applications, offering benefits such as flexibility and enhanced adhesion.

- Specialty Coatings: ACL also develops specialty coatings that meet specific industry standards. These can include coatings designed for extreme weather conditions, anti-fouling properties, and additional layers of protection against mechanical wear.

Engineering and Handling Capabilities

A standout feature of ACL is its engineering capabilities, supported by a robust facility equipped with a 50-ton crane capacity. This allows ACL to handle large and complex components, such as pipe spools, heat exchangers, and, notably, wind turbines. The ability to manage oversized equipment efficiently streamlines the coating process and reduces turnaround times.

Moreover, the onsite engineering services enable ACL to collaborate closely with clients, ensuring that every aspect of the coating application is optimized for performance and longevity. This customer-centric approach fosters innovation and enhances the reliability of wind turbine components.

Environmental Considerations

As the wind energy sector continues to expand, the focus on sustainable practices is more critical than ever. ACL is committed to minimizing its environmental footprint through eco-friendly coating options. The use of low-VOC (volatile organic compounds) coatings, for instance, not only meets regulatory standards but also reduces harmful emissions during the application process.

Additionally, the durability of ACL’s coatings contributes to sustainability by prolonging the life of wind turbine components. This reduces the need for frequent replacements and repairs, further decreasing waste and resource consumption.

Challenges in the Coating Industry

Despite the advancements in coating technologies, the industry faces challenges that require ongoing innovation. Factors such as fluctuating raw material prices, stringent regulatory requirements, and the need for rapid advancements in coating performance necessitate a proactive approach.

ACL remains at the forefront of addressing these challenges by investing in research and development. Collaborating with manufacturers and industry partners enables ACL to stay updated on emerging trends and technologies, ensuring that its coating solutions remain competitive and effective.

Future Trends in Wind Turbine Coatings

Looking ahead, several trends are shaping the future of wind turbine coatings:

- Smart Coatings: The development of smart coatings that can monitor their own condition and alert operators to potential issues is on the rise. These coatings can enhance maintenance strategies and reduce downtime.

- Nanotechnology: Advances in nanotechnology are leading to coatings with improved properties, such as increased hardness, flexibility, and resistance to environmental factors.

- Sustainability Innovations: The push for more sustainable practices will continue to drive innovations in eco-friendly coatings, focusing on recyclability and reduced environmental impact.

- Enhanced Customization: As the demand for specific performance attributes grows, the ability to customize coatings to meet precise requirements will become increasingly important.

Wind turbine coatings play a vital role in the performance and longevity of renewable energy infrastructure. With leaders like ACL pushing the boundaries of coating technologies, the industry is well-positioned to meet the challenges of the future. By combining advanced engineering capabilities, sustainable practices, and innovative coating solutions, ACL is setting a standard that will benefit not only wind energy but the broader push towards a more sustainable world. As we move forward, the continued evolution of wind turbine coatings will be essential in supporting the growth of renewable energy and protecting our planet for future generations.

Back