In the modern industrial landscape, the integrity of pipeline systems is paramount, particularly in the oil, gas, and water sectors. Automatic Coating Ltd. (ACL) stands out as a leader in providing high-performance coatings essential for protecting these critical infrastructures from corrosion and chemical degradation. Based in Toronto, ACL boasts over 40 years of experience and has solidified its reputation through its commitment to quality and innovation.

The Importance of Pipeline Coatings

Pipelines are vital for transporting oil, gas, and water across vast distances. However, they are constantly exposed to harsh environmental conditions and corrosive substances that can compromise their structural integrity. This is where coatings play a crucial role. They act as a barrier, preventing corrosive elements from reaching the underlying metal and significantly extending the lifespan of the pipes.

Corrosion Resistance: The primary function of pipeline coatings is to prevent corrosion. Corrosion can lead to leaks, environmental hazards, and significant economic losses. By using advanced coatings, companies can mitigate these risks effectively.

Chemical Resistance: In addition to corrosion, pipelines often encounter various chemicals. Coatings must be tailored to withstand these substances without degrading. This is particularly important in the oil and gas industry, where pipelines transport a range of volatile materials.

Durability: High-quality coatings are designed to endure extreme temperatures and pressures, ensuring that pipelines remain functional under demanding conditions.

Automatic Coating Ltd.: Expertise and Capabilities

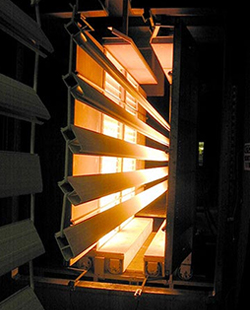

Automatic Coating has developed extensive expertise in applying Fusion Bond Epoxy (F.B.E) and liquid coatings. These coatings are specifically designed for both the interior and exterior of pipes and fittings, which can reach diameters of up to 16 feet and lengths of 100 feet. This capability is essential for a variety of industries, from hydroelectric power generation to natural gas distribution.

Certification and Trust: ACL is a certified coater for major companies, including Enbridge, TransCanada, Union Gas, GazMetro, and ElPaso Pipeline. This certification speaks volumes about the trust these industry giants place in ACL’s quality and reliability.

Innovative Solutions: One of ACL’s most significant achievements is the successful application of internal coatings for the largest diameter pipes in North America, specifically designed for water cooling in the hydroelectric industry. This project required cutting-edge technology and expertise, which ACL delivered, showcasing their capability to meet demanding specifications.

Coating Techniques and Technologies

ACL utilizes various advanced coating techniques to ensure optimal performance:

- Fusion Bond Epoxy (F.B.E): This method involves applying a thermosetting epoxy powder to the surface of the pipe, which is then heated to create a strong bond. F.B.E coatings are known for their excellent adhesion and resistance to corrosion.

- Plural Component Coatings: This involves mixing two components to create a coating that offers superior chemical and abrasion resistance. This type of coating is ideal for environments that expose pipelines to harsh chemicals and extreme conditions.

- High-Performance Liquid Coatings: These coatings provide an additional layer of protection against corrosive environments. They can be tailored to meet specific industry requirements, ensuring compliance with regulations and performance standards.

Projects and Partnerships

Automatic Coating has played a crucial role in several high-profile projects across North America. Their work on the Keystone Project and projects for Enbridge and TransCanada highlights their capacity to deliver quality and innovation on a large scale. These projects often require intricate planning and execution, with stringent quality control measures in place to ensure that every coating meets the specified requirements.

Collaboration with Utilities: ACL has partnered with major utilities across the continent, providing coatings that help enhance the reliability and safety of their operations. This collaboration not only showcases ACL’s expertise but also underscores the importance of strong partnerships in achieving industry goals.

The Future of Pipeline Coatings

As the demand for energy continues to rise, so does the need for efficient and reliable pipeline systems. The role of coatings will only grow in importance, with advancements in technology paving the way for even more robust solutions. ACL is well-positioned to lead in this arena, thanks to its commitment to innovation and quality.

Sustainability Considerations: With an increasing focus on sustainability, future coatings will likely need to address environmental concerns. This may involve developing eco-friendly materials and processes that minimize environmental impact while maintaining performance standards.

Adaptation to New Challenges: The oil and gas industries face ongoing challenges, including fluctuating market conditions and regulatory changes. Companies like ACL must be agile, adapting their products and services to meet these evolving demands.

Automatic Coating Ltd. has established itself as a premier provider of corrosion and chemical resistant coatings for pipelines in Toronto and beyond. With over 40 years of experience, a strong portfolio of successful projects, and a commitment to innovation, ACL is well-equipped to meet the challenges of the oil, gas, and water sectors. As the industry evolves, so too will ACL, ensuring that they continue to provide the highest quality coatings to protect critical infrastructure. Through their expertise and dedication, ACL is not only safeguarding pipelines but also contributing to a more reliable and sustainable energy future.

Back