In the marine and defense industries, the challenge of corrosion is a significant concern, particularly for naval vessels that operate in harsh maritime environments. Corrosion not only affects the structural integrity of ships and submarines but also incurs substantial maintenance costs and operational downtime. Recognizing these challenges, ACL has developed the patented Tidal Coat Corrosion Protection System, which has become a cornerstone in the defense equipment coating sector. This innovative technology has demonstrated its effectiveness in prolonging the lifespan of naval vessels and components, ensuring that they remain operational in the face of relentless marine conditions.

The Tidal Coat System: Overview

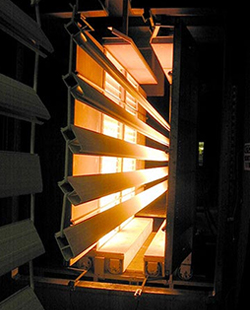

The Tidal Coat system employs a dual immersion polymer powder process, offering an unparalleled level of corrosion protection. This advanced method provides an impressive five-year limited warranty on the coatings, although many coated parts exhibit a lifespan exceeding ten years. The unique attributes of this system stem from its multi-layer process, which effectively encapsulates weldments and castings, delivering a robust barrier against corrosive elements.

One of the critical advantages of the Tidal Coat system is its ability to uniformly cover inaccessible areas where conventional coatings often fail. This comprehensive coverage is essential in marine applications, as many components have complex geometries and intricate designs that can trap moisture and facilitate corrosion. By utilizing a fusion-bonded approach, ACL ensures that even the most difficult-to-reach surfaces are protected, significantly reducing the risk of corrosion-related failures.

Applications in the Naval and Defense Industry

The U.S. Navy and the Canadian Navy have widely deployed the Tidal Coat system on various vessels, including destroyers and offshore patrol ships such as the Kingston, Halifax, and Arctic Offshore Patrol System ships. ACL has coated thousands of superstructure components for the defense industry, which has proven instrumental in prolonging the lifespan of critical maritime assets. This proactive approach to corrosion control has resulted in significant cost savings for military operations, reducing the frequency and intensity of maintenance interventions.

In addition to surface components, ACL has successfully coated thousands of underwater warfare components designed for continuous submersion in seawater. Many of these components have remained operational for over 20 years, a testament to the durability and reliability of the Tidal Coat system. By utilizing approved military specification coatings, ACL ensures compliance with stringent defense industry standards while providing solutions that withstand the rigors of marine environments.

Cost Savings and Operational Efficiency

The financial implications of effective corrosion control in the marine and defense sectors are substantial. Corrosion can lead to extensive repairs, replacement of parts, and extended vessel downtimes, all of which can significantly impact operational readiness. By implementing the Tidal Coat system, the defense industry has experienced millions of dollars in savings related to maintenance costs. These savings stem not only from the extended lifespan of coated components but also from reduced labor and material expenditures associated with frequent repairs.

Furthermore, the enhanced durability of ACL’s coatings translates to increased operational efficiency. Naval vessels can spend more time at sea, executing missions without the constant need for maintenance and repair. This shift allows military resources to be allocated more effectively, enhancing overall operational capabilities.

Environmental Considerations

In today’s world, environmental sustainability is a pressing concern, particularly in industries like marine and defense. ACL is committed to minimizing environmental impact through innovative technologies. The Tidal Coat system is designed with eco-friendliness in mind, utilizing materials and processes that reduce harmful emissions and waste. By focusing on sustainable practices, ACL not only meets regulatory requirements but also supports the broader goals of environmental stewardship within the defense sector.

Future Developments and Innovations

Looking ahead, ACL is dedicated to further advancing its corrosion protection technologies to meet the evolving needs of the marine and defense industries. Continuous research and development efforts are aimed at enhancing the performance of coatings and exploring new materials that can offer even greater resistance to corrosion and wear. Collaboration with industry partners and military organizations will play a crucial role in these advancements, ensuring that ACL remains at the forefront of innovation in defense equipment coating.

Moreover, as naval operations expand into more challenging environments, such as polar regions and deeper oceanic explorations, the need for advanced corrosion protection systems will only grow. ACL is prepared to meet these challenges head-on, leveraging its expertise to provide solutions that enhance the longevity and reliability of defense assets.

The marine and defense industries face unique challenges when it comes to corrosion management, but ACL’s Tidal Coat Corrosion Protection System stands out as a revolutionary solution. With its advanced dual immersion polymer powder process, this system provides exceptional protection, ensuring that naval vessels and their components can withstand the rigors of maritime environments. The significant cost savings and operational efficiencies gained through the use of Tidal Coat demonstrate its value to military operations.

As ACL continues to innovate and develop new corrosion protection technologies, the company is well-positioned to support the needs of the defense industry, enhancing the longevity and effectiveness of naval operations. In a field where reliability and performance are paramount, ACL’s commitment to excellence ensures that its coatings will remain a vital part of the marine and defense landscape for years to come.

Back