Heavy equipment plays a crucial role in various industries, including construction, agriculture, and mining. These machines are designed to perform demanding tasks, often in harsh environments. To ensure optimal performance and longevity, proper maintenance and protection of these assets are vital. One of the key elements in safeguarding heavy equipment is through effective coating solutions. Heavy Equipment Coating ACL has established itself as a leader in this area, renowned for its ability to handle large and complex projects in Toronto and beyond.

The Importance of Coatings

Coatings serve multiple purposes for heavy equipment. They provide protection against corrosion, abrasion, and environmental factors, which can significantly affect a machine’s lifespan and operational efficiency. Without adequate protection, heavy equipment is vulnerable to rust, wear, and tear, leading to costly repairs or replacements.

In industries like construction and agriculture, where equipment is frequently exposed to harsh conditions, the choice of coating can make a significant difference. For instance, machines that operate in muddy or wet environments are particularly prone to corrosion. A robust coating can create a barrier that keeps moisture at bay, thus prolonging the equipment’s service life.

Innovative Solutions by ACL

Heavy Equipment Coating ACL has made a name for itself by offering innovative coating solutions tailored to the needs of heavy machinery. The company specializes in handling large-scale projects, accommodating equipment as massive as 75 tons. This capability sets ACL apart, allowing them to service a wide range of industries efficiently.

One of the key processes employed by ACL is pretreatment, which is critical for ensuring that coatings adhere properly to the surface of the equipment. The company offers two primary pretreatment methods: chemical washing and grit blasting.

- Chemical Wash: This method involves using specialized chemicals to clean the surface of the equipment. The chemical wash removes dirt, grease, and existing rust, creating a clean surface that promotes better adhesion of the coating. This step is vital for ensuring the durability of the protective layer.

- Grit Blasting: This more abrasive method involves propelling fine particles against the surface of the equipment. Grit blasting not only cleans the surface but also creates a rough texture that improves the bonding of the coating. This is especially beneficial for older equipment with more challenging surfaces.

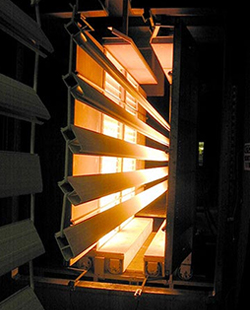

Following pretreatment, ACL applies both powder and liquid coatings, depending on the specific needs of the equipment and the environments in which they operate. Powder coatings, known for their durability and resistance to chipping and fading, are an excellent choice for equipment that faces heavy wear. Liquid coatings, on the other hand, may provide superior coverage and flexibility, making them suitable for a variety of applications.

Reducing Warranty Failures

A significant advantage of ACL’s comprehensive coating process is the reduction of costly coating warranty failures. Warranty issues can arise from improper application or inadequate surface preparation, leading to peeling, chipping, or other failures that require expensive repairs. ACL’s meticulous pretreatment and coating application processes have effectively minimized these risks, ensuring that the coated parts stand the test of time.

Customers can feel confident that their heavy equipment will perform reliably after being treated by ACL. This assurance not only enhances customer satisfaction but also strengthens ACL’s reputation as a trusted provider of industrial solutions.

Flexibility in Service

One of the hallmarks of Heavy Equipment Coating ACL is its flexibility. The company recognizes that different industries have different requirements, and no two projects are alike. Whether dealing with construction equipment, farm machinery, or mining vehicles, ACL tailors its services to meet the specific needs of each customer.

This adaptability extends to the types of coatings used, the pretreatment methods selected, and even the scheduling of services to minimize downtime for clients. ACL works closely with customers to understand their operational demands and provide solutions that align with their timelines and budgets.

Environmental Considerations

In addition to enhancing the longevity and performance of heavy equipment, ACL is also mindful of environmental impact. The company employs eco-friendly practices in its coating processes, ensuring that waste is minimized and hazardous materials are handled responsibly. This commitment to sustainability not only benefits the environment but also aligns with the increasing regulatory requirements in many industries.

Heavy Equipment Coating ACL has established itself as a leader in the industrial coating sector, known for its innovative solutions, flexibility, and commitment to quality. By employing advanced pretreatment techniques and high-performance coatings, ACL protects heavy machinery against the rigors of demanding environments, ensuring that these vital assets continue to perform at their best.

The reduction of warranty failures is a testament to ACL’s expertise and meticulous approach, making the company a preferred choice for businesses looking to safeguard their investments in heavy equipment. As industries continue to evolve and face new challenges, ACL remains at the forefront, ready to deliver effective solutions that enhance the performance and durability of heavy machinery. Whether for construction, agriculture, or mining, the coatings provided by ACL are more than just a layer of protection; they are an essential component in the lifecycle of heavy equipment.

Back