Food processing is a crucial segment of the agricultural industry, transforming raw ingredients into consumable products. This sector employs various techniques and technologies to ensure that food is safe, nutritious, and appealing to consumers. Among the essential components of food processing are industrial applications that improve efficiency, maintain quality, and adhere to stringent safety regulations.

Overview of Food Processing

The food processing industry encompasses a wide range of activities, including the preparation, preservation, packaging, and distribution of food products. The primary goal is to enhance the shelf life of foods, retain their nutritional value, and ensure safety for consumers. Techniques used in food processing include canning, freezing, drying, and fermentation, among others.

Importance of Compliance

Compliance with regulations set by organizations such as the Food and Drug Administration (FDA) and the National Sanitation Foundation (NSF) is paramount in the food processing industry. These standards ensure that food products are safe for consumption and meet quality expectations. Non-compliance can lead to serious health risks for consumers and significant financial losses for companies.

ACL’s Role in Food Processing

In Toronto, ACL has made significant contributions to the food processing industry through its innovative use of powder and liquid coatings. These coatings are essential for finishing food hoppers, vats, and other contact parts used in food handling and processing. The coatings not only enhance the appearance of equipment but also provide essential protective features that are critical for maintaining hygiene and safety in food production.

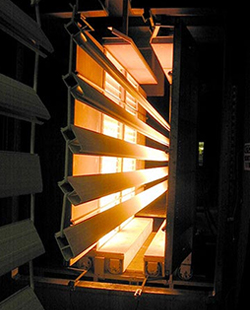

Powder Coating

Powder coating is a finishing process that involves applying a dry powder to the surface of materials. The coated items are then heated to create a durable, protective layer. In food processing, powder coatings are particularly beneficial for several reasons:

- Durability: The coatings provide excellent resistance to scratches, chipping, and corrosion, ensuring that equipment remains intact even under demanding conditions.

- Hygiene: Powder coatings can be formulated to be non-toxic and resistant to bacteria, making them suitable for food contact surfaces. This is essential for maintaining sanitation standards.

- Ease of Cleaning: Smooth powder-coated surfaces can be easily cleaned, which is vital in preventing contamination during food processing.

- Customization: Powder coatings can be customized in various colors and finishes, allowing companies to brand their equipment and improve workplace aesthetics.

Liquid Coating

Liquid coatings are another vital application in the food processing industry. Unlike powder coatings, liquid coatings are applied in a wet form and then cured to form a protective layer. The benefits of liquid coatings include:

- Versatility: Liquid coatings can be applied to a wide range of surfaces, including intricate shapes and components that might be challenging for powder coating.

- Chemical Resistance: Many liquid coatings are designed to withstand exposure to harsh chemicals, which is essential in environments where cleaning agents are frequently used.

- Temperature Tolerance: Liquid coatings can be engineered to withstand high temperatures, making them suitable for applications such as cooking equipment and ovens.

- Enhanced Aesthetics: Liquid coatings provide a smooth finish that can enhance the visual appeal of food processing equipment.

Applications in Food Processing

The applications of powder and liquid coatings extend to various aspects of food processing, including:

- Food Storage: Coated hoppers and vats help in the safe storage of raw ingredients. The coatings prevent contamination and maintain the integrity of the food.

- Processing Equipment: Machines used in the processing of food, such as mixers, conveyors, and blenders, benefit from protective coatings that enhance performance and extend lifespan.

- Packaging Equipment: Coated surfaces on packaging machinery ensure that products remain uncontaminated during the packing process, adhering to safety standards.

- Cleaning Equipment: Equipment used for cleaning and sanitizing food processing areas also requires protective coatings to withstand exposure to cleaning chemicals.

Environmental Considerations

In recent years, the food processing industry has increasingly focused on sustainability and environmental responsibility. Many coatings, both powder and liquid, are now available in eco-friendly formulations. These coatings minimize the environmental impact by reducing volatile organic compounds (VOCs) and utilizing recyclable materials. Additionally, companies are adopting practices that ensure waste is minimized during the coating application process.

Challenges and Innovations

Despite the advancements in coating technology, the food processing industry faces several challenges, including:

- Regulatory Changes: Staying compliant with ever-evolving FDA and NSF regulations requires constant innovation and adaptation in coating materials and application processes.

- Cost Management: Balancing the cost of high-quality coatings with budget constraints can be challenging, especially for small to medium-sized enterprises.

- Technological Integration: Integrating new coating technologies into existing manufacturing processes requires investment and training, which can be a barrier for some companies.

However, innovations in material science and coating technologies continue to address these challenges. Companies are developing smarter, more efficient coatings that enhance safety, durability, and ease of use, ensuring that food processing can continue to evolve in a competitive marketplace.

The food processing industry plays a vital role in ensuring that food is safe, nutritious, and appealing. Companies like ACL are at the forefront of innovation, utilizing powder and liquid coatings to enhance equipment used in food handling and processing. By adhering to stringent safety standards and focusing on sustainability, the industry can meet the growing demands of consumers while ensuring the highest quality of food products. As technology advances, the future of food processing looks promising, with continued improvements in efficiency, safety, and environmental responsibility.

Back