Introduction

In the fast-paced world of electronics and telecommunications, the demand for high-quality, durable equipment is paramount. Companies like ACL have carved out a niche in providing specialized solutions that ensure longevity and performance in electronic components. This article explores the significance of coating processes in the electronics and telecommunications industries, highlighting the pretreatment, masking, and coating requirements for products such as PBX telephone equipment.

The Importance of Coating in Electronics

Coatings play a critical role in protecting electronic components from environmental factors that can lead to degradation. In applications ranging from consumer electronics to complex telecommunications systems, coatings serve several essential functions:

- Corrosion Resistance: Electronic devices are often exposed to moisture, chemicals, and other corrosive elements. Coatings create a barrier that protects sensitive components, ensuring their functionality over time.

- Thermal Management: Many electronic devices generate heat during operation. Proper coatings can help manage thermal properties, dissipating heat more effectively and prolonging the lifespan of the equipment.

- Electrical Insulation: Coatings can provide insulation, preventing short circuits and ensuring safe operation of electronic devices. This is especially critical in densely packed circuitry, where even the smallest error can lead to failures.

- Aesthetic Appeal: Beyond protection, coatings can enhance the visual appeal of devices. A well-applied coating can improve the overall look of the product, making it more attractive to consumers and clients.

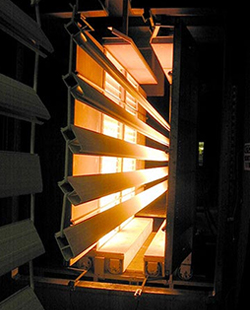

Coating Process Overview

The coating process for electronic and telecommunications equipment involves several crucial steps: pretreatment, masking, and the actual coating application. Each stage is vital to achieving the desired quality and performance.

1. Pretreatment

Before any coating can be applied, the surface of the equipment must be properly prepared. This step, known as pretreatment, involves:

- Cleaning: Removal of contaminants such as dust, oil, and oxidation is essential. Techniques such as ultrasonic cleaning, solvent cleaning, or abrasive blasting may be employed.

- Surface Activation: Depending on the type of coating being used, the surface may need to be treated to improve adhesion. Processes such as chemical etching or plasma treatment can create a more suitable surface for bonding.

- Dehydration: Ensuring the surface is completely dry is critical, especially when working with moisture-sensitive coatings.

2. Masking

Masking is a key step in the coating process, especially in electronics where only specific areas need to be coated. Effective masking involves:

- Precision Application: Using high-quality masking materials, technicians can protect areas that should remain uncoated, ensuring that connections and critical components are not compromised.

- Custom Solutions: Given the variety of equipment designs, masking solutions must be tailored to each project. This may involve creating custom stencils or using specialized tapes that can withstand the coating process.

3. Coating Application

The actual application of the coating is where the protective magic happens. Several methods can be employed:

- Spray Coating: Common in many applications, spray coating allows for even coverage and is suitable for complex shapes.

- Dip Coating: This method involves submerging the equipment in a coating solution, providing thorough coverage, especially for intricate geometries.

- Electrostatic Coating: Utilizing electric charge, this method ensures an even distribution of coating material, which can be particularly effective for powder coatings.

- Vacuum Deposition: For certain advanced applications, coatings can be applied in a vacuum environment, allowing for thin, uniform layers that are ideal for high-tech electronics.

Quality Control and Testing

Once the coating process is complete, rigorous quality control is essential to ensure the finished product meets industry standards. This may include:

- Adhesion Testing: Checking the bond strength between the coating and the substrate ensures that the coating will perform as intended over time.

- Environmental Testing: Exposing the coated equipment to extreme conditions such as humidity, temperature fluctuations, and corrosive environments can help predict long-term performance.

- Visual Inspection: Inspecting the coating for defects such as bubbles, runs, or uneven surfaces ensures that the product not only performs well but also looks good.

Industry Applications

In the telecommunications sector, companies such as ACL specialize in providing coating solutions for a range of products, including PBX telephone equipment in Toronto. These systems are critical for business communications, and the reliability of their components is paramount.

- PBX Systems: These systems, which manage internal and external calls, rely on numerous electronic components. Coating helps protect these components from interference and degradation, ensuring reliable performance.

- Networking Equipment: Routers, switches, and other networking devices are exposed to various environmental factors. High-quality coatings enhance their durability and operational efficiency.

- Consumer Electronics: As the market for smartphones, tablets, and other devices continues to grow, the need for robust protective coatings becomes more critical.

- Aerospace and Defense: In these industries, equipment must endure extreme conditions. Specialized coatings help ensure that these systems remain operational, even under harsh circumstances.

The coating processes utilized in the electronics and telecommunications industries are essential for enhancing the performance and longevity of critical equipment. With a comprehensive understanding of pretreatment, masking, and coating requirements, companies like ACL provide vital services that ensure products such as PBX telephone equipment not only function effectively but also maintain their integrity over time. By investing in high-quality coating solutions, businesses can enhance product durability, performance, and aesthetic appeal, ultimately leading to greater customer satisfaction and loyalty in a competitive market.

Back