The nuclear industry operates under stringent safety and regulatory standards, necessitating the use of specialized coatings that can withstand harsh environments and provide long-lasting protection. Automatic Coating Limited (ACL) excels in this domain, utilizing advanced techniques such as fusion bond epoxy and liquid coatings to enhance the durability and functionality of components used in nuclear applications. With certifications such as ISO 9001:2015 and SSPC QP3, ACL ensures that its coatings meet the highest standards of quality and performance.

Importance of Coatings in the Nuclear Industry

Coatings in the nuclear sector serve multiple critical purposes:

- Corrosion Resistance: Nuclear facilities face extreme conditions, including exposure to chemicals, radiation, and high temperatures. Coatings protect metal surfaces from corrosive environments, significantly extending the life of components such as piping, tanks, and containment structures.

- Radiation Protection: Certain coatings are designed to mitigate radiation exposure. These coatings help shield both personnel and sensitive equipment from harmful radiation, ensuring safety within the facility.

- Thermal Protection: High-performance coatings can also provide thermal insulation, protecting underlying materials from thermal stresses and improving the overall efficiency of nuclear systems.

- Aesthetic and Identification: While functionality is paramount, coatings can also serve aesthetic purposes, such as color coding for easy identification and maintenance.

Types of Coatings Used

Fusion Bond Epoxy Coatings

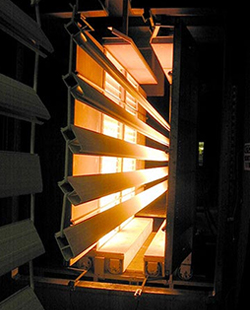

Fusion bond epoxy (FBE) coatings are a popular choice in the nuclear industry due to their excellent adhesion and resistance to a wide range of chemicals and temperatures. The application process involves the following steps:

- Surface Preparation: Proper surface preparation is essential to ensure the coating adheres effectively. This often involves abrasive blasting to remove contaminants and create a rough surface for better adhesion.

- Coating Application: The epoxy powder is applied electrostatically and then cured in an oven. This process creates a continuous, impermeable layer that protects the substrate.

- Quality Control: Post-application, coatings undergo rigorous testing to ensure they meet performance standards. This includes checks for adhesion, thickness, and overall integrity.

The benefits of FBE coatings include:

- High Chemical Resistance: Effective against various corrosive substances, making them ideal for the nuclear environment.

- Durability: Excellent impact resistance and mechanical strength.

- Long Lifespan: Reduces the frequency of maintenance and replacement, which is crucial in high-stakes settings like nuclear facilities.

Liquid Coatings

Liquid coatings also play a vital role in the nuclear industry. They can be tailored to specific requirements and are versatile in application. The key advantages of liquid coatings include:

- Custom Formulations: Liquid coatings can be formulated to meet specific performance criteria, including UV resistance, thermal stability, and additional chemical resistance.

- Ease of Application: These coatings can be applied using various methods, including spraying, brushing, or rolling, making them adaptable to different shapes and sizes of components.

- Rapid Curing Times: Many liquid coatings cure quickly, which can reduce downtime during maintenance or installation processes.

Liquid coatings provide effective barriers against moisture and corrosion while offering flexibility in application techniques.

Quality Assurance and Certification

Automatic Coating Limited’s commitment to quality is evident in its certifications. Being ISO 9001:2015 certified ensures that ACL follows stringent quality management processes, leading to consistent and reliable product outcomes. This certification involves regular audits and a commitment to continuous improvement in processes and services.

Additionally, ACL’s SSPC QP3 certification demonstrates compliance with industry standards for surface preparation and coating application, particularly in complex environments like nuclear facilities. This certification ensures that ACL’s operations meet the expectations of clients in terms of quality, reliability, and safety.

Challenges in Coating for Nuclear Applications

While ACL excels in providing coatings for the nuclear industry, several challenges must be navigated:

- Regulatory Compliance: The nuclear industry is highly regulated, and coatings must comply with various safety and environmental standards. This can require extensive documentation and testing.

- Environmental Factors: Coatings must be formulated to withstand not just corrosion but also the unique environmental conditions present in nuclear facilities, including temperature fluctuations and radiation exposure.

- Material Compatibility: The coatings used must be compatible with various materials used in nuclear applications, including metals, plastics, and composites. This requires careful selection of coating formulations to ensure performance and longevity.

- Performance Longevity: Given the critical nature of nuclear applications, coatings must perform reliably over extended periods, necessitating rigorous testing and validation processes.

Future Trends in Nuclear Coatings

As the nuclear industry evolves, so too do the requirements for coatings. Several trends are emerging that could shape the future of coatings in this sector:

- Advancements in Coating Technologies: Innovations in material science are leading to the development of new coatings that offer even greater durability and resistance to extreme conditions.

- Sustainability Focus: With increasing emphasis on sustainability, there is a push towards developing eco-friendly coatings that reduce environmental impact without compromising performance.

- Smart Coatings: The integration of smart technologies into coatings is on the rise. These coatings can provide real-time feedback on their condition, alerting operators to potential issues before they become critical.

- Increased Automation: Advances in automation and robotics for coating application are likely to improve efficiency and consistency, further enhancing the reliability of coatings in nuclear applications.

Automatic Coating Limited stands out as a leader in providing high-performance coatings for the nuclear industry. With its expertise in fusion bond epoxy and liquid coatings, combined with rigorous quality assurance certifications, ACL ensures that components meet the demanding standards of safety and durability required in nuclear applications. As the industry continues to evolve, ACL remains at the forefront of innovation, committed to delivering coatings that enhance the performance and safety of nuclear facilities for years to come.

Back