The aircraft industry is a complex and highly regulated sector, demanding the utmost in quality and performance from every component. One critical aspect of aircraft manufacturing and maintenance is the application of coatings. These coatings serve various functions, from enhancing aesthetic appeal to providing crucial protection against wear, corrosion, and environmental factors. ACL (Aerospace Coating Ltd) has established itself as a leader in this niche, earning the prestigious AS9100 aerospace certification, which underscores its commitment to quality and excellence.

The Importance of Coatings in Aviation

Coatings play a vital role in the longevity and reliability of aircraft components. Given the extreme conditions that aircraft are subjected to—ranging from high-altitude low temperatures to the corrosive effects of humidity and fuel—proper coating application is essential. The right coatings can extend the lifespan of parts, reduce maintenance costs,and enhance safety.

Key Applications of Aircraft Coatings

- Landing Gear Parts: The landing gear is one of the most critical components of an aircraft, subjected to immense stress during takeoff and landing. ACL applies high-quality powder coatings to landing gear parts to enhance their durability and resistance to wear and tear. These coatings provide a tough exterior that can withstand repeated impacts and abrasions while maintaining structural integrity.

- Moving Parts: Aircraft have numerous moving parts, including flaps, ailerons, and control surfaces. These components are designed to operate seamlessly under various conditions. Powder coatings can be applied to these moving parts to reduce friction, minimize wear, and improve performance. This ensures that parts operate smoothly over their lifespan, reducing the likelihood of mechanical failures.

- Structural Components: The structural integrity of an aircraft is paramount for safety. ACL’s coatings can be applied to various structural components, including struts and bulkheads, to protect against corrosion and fatigue. This added layer of protection extends the life of these critical parts, ultimately enhancing the aircraft’s reliability.

- Door Handles and Railings: Aesthetic considerations are also important in aircraft design. Coatings applied to door handles and hand railings not only improve their appearance but also protect them from frequent handling and environmental exposure. This is especially relevant in commercial aviation, where passenger experience is key.

- Abrasion-Resistant Coatings: Many aircraft components are subject to abrasions, whether from the environment or operational wear. ACL specializes in applying abrasion-resistant coatings that can significantly enhance the durability of these components. This is particularly beneficial in areas exposed to frequent contact or friction, ensuring they remain functional and visually appealing over time.

Collaboration with Major Manufacturers

ACL’s reputation for quality has made it a trusted partner for leading aircraft manufacturers such as Boeing and Bombardier. Collaborating with these industry giants, ACL has been instrumental in enhancing the durability of various components. By applying innovative coating solutions, ACL has helped these companies achieve longer part lifespans and significantly reduce maintenance costs.

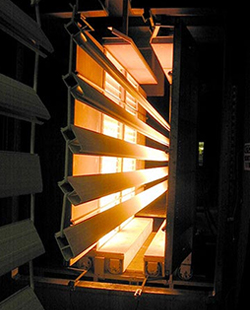

The Benefits of Powder Coating

One of the standout techniques used by ACL is powder coating. Unlike traditional liquid coatings, powder coating is applied in a dry form and cured under heat to create a tough, durable finish. The advantages of powder coating in the aircraft industry include:

- Environmental Sustainability: Powder coatings produce minimal volatile organic compounds (VOCs), making them a more environmentally friendly option.

- Durability: Powder coatings are known for their hardness and resistance to chipping, scratching, and fading. This ensures that parts remain functional and aesthetically pleasing even under harsh conditions.

- Customization: Powder coatings can be produced in a wide range of colors and finishes, allowing for customization to meet specific aesthetic and functional requirements.

- Cost Efficiency: The durability of powder coatings can lead to lower maintenance costs, as parts need to be replaced or re-coated less frequently.

The aircraft industry continues to evolve, with increasing demands for safety, efficiency, and sustainability. Coatings, particularly powder coatings, play an essential role in meeting these demands. ACL’s AS9100 certification reflects its commitment to quality and excellence, ensuring that its coating applications enhance the performance and longevity of aircraft components.

By partnering with leading manufacturers and focusing on innovative coating solutions, ACL is poised to continue making significant contributions to the aircraft industry. Through their expertise in applying high-quality coatings, ACL not only helps extend the lifespan of critical parts but also supports the overarching goal of enhancing safety and reliability in aviation. As the industry moves forward, the importance of advanced coating applications will only continue to grow, solidifying ACL’s position as a key player in this vital sector.

Back