The Most Technically Diverse in North America & Toronto

When it comes to coating services, especially in North America and specifically Toronto, Automatic Coating stands out as a leader in innovation and quality. The company’s commitment to providing the most technically advanced solutions in the industry makes it an ideal choice for businesses seeking superior protection for their assets. Below, we explore the various services offered, highlighting the technological diversity and expertise that Automatic Coating brings to the table.

Technologically Advanced Coating Solutions

Automatic Coating prides itself on being at the forefront of technology with its state-of-the-art powder and liquid coating facilities. The company has invested heavily in advanced equipment and processes to ensure the highest quality finishes. Their facilities are designed to meet diverse industry needs, making them the most technically advanced in North America.

- Powder Coating

Powder coating is known for its durability and resilience. Automatic Coating utilizes cutting-edge equipment that guarantees a smooth, uniform finish with excellent adhesion. The fully automated powder applicators are controlled by PLC (Programmable Logic Controller) systems, ensuring repeatable quality across large production runs. The patented fusion bond technologies further enhance the coating’s performance, making it ideal for demanding environments.

- Liquid Coating

Liquid coatings are another specialty area for Automatic Coating. With a focus on plural component coatings, the company can offer tailored solutions that cater to specific project requirements. The liquid coating services include tank lining, which provides exceptional protection against corrosion and wear, ensuring the longevity of the infrastructure.

- Tidal Coat Service

The Tidal Coat service represents a groundbreaking approach to coating application. Utilizing immersion techniques, this service allows for an even coating that reaches every nook and cranny of the items being coated. This is particularly beneficial for complex geometries where traditional methods may fall short. The water-tight door systems in Tidal Coat machines ensure efficiency and reduce the risk of contamination.

Comprehensive Fabrication Services

Beyond just coating, Automatic Coating offers a range of fabrication services that complement their core offerings. This includes custom design and fabrication capabilities that are essential for creating specialized equipment for various industries.

- Blasting and Coating Equipment

The company provides advanced equipment for blasting and coating, ensuring that surface preparation meets the highest standards. This is crucial for achieving optimal adhesion and longevity of the coating. Their services include automated stripping and blasting, which are both efficient and environmentally friendly.

- Marine Corrosion and Electrical Insulation

Automatic Coating also focuses on producing components for marine applications. Their expertise in marine corrosion prevention and electrical insulation ensures that critical parts and equipment are protected against the harshest environments.

- Pipeline Corrosion Equipment

With specialized equipment designed for pipeline applications, such as girth weld coaters and transducer tubes, Automatic Coating addresses the unique challenges of the oil and gas industry. Their commitment to quality and compliance with industry standards makes them a trusted partner for pipeline projects.

Consulting Services for Coating Shops

In addition to their core services, Automatic Coating offers consulting services that encompass layout, design, and training for coating shops. This includes:

- Best Practices Outside the GTA

The team at Automatic Coating shares their extensive knowledge and experience to help other businesses optimize their coating operations. Whether it’s enhancing workflow or implementing best practices, the consulting services aim to elevate industry standards.

- Field Stripping, Blasting, and Coating

Automatic Coating’s field services employ the most advanced automated coating equipment available. Their commitment to environmentally friendly practices is evident in their integrated spray units, which result in a one-third reduction in greenhouse gas emissions.

Environmental Responsibility

In today’s environmentally conscious world, Automatic Coating leads the way with initiatives that minimize ecological impact. Their use of circulating coatings ensures that materials arrive on-site ready to coat, reducing waste and enhancing efficiency. The environmentally friendly automated stripping of harmful materials like PCBs and asbestos is another testament to their commitment to safety and sustainability.

Certifications and Approvals

Automatic Coating has earned a solid reputation due to its rigorous quality standards and certifications. They are:

- ISO 9001-2008 Certified: This certification indicates that Automatic Coating adheres to international standards for quality management systems.

- Approved by Major Industry Players: They are recognized by major oil and gas companies, including TransCanada, Enbridge, and Spectra Energy, highlighting their trustworthiness and quality.

- Military Approved: The company meets the stringent requirements set forth by the U.S. and Canadian military, ensuring that their coatings can withstand the toughest conditions.

Quality Infrastructure

Automatic Coating’s commitment to quality infrastructure is evident in its automated systems. The company’s facilities span 70,000 square feet with a 2-acre laydown area/storage yard. This ample space allows for high-volume production and efficient logistics, ensuring quick turnaround times without compromising on quality.

- Electrostatic Coating Lines

The automated electrostatic coating lines are a key component of their operation, allowing for precise application and excellent coverage. The PLC-controlled systems not only enhance repeatability but also improve overall efficiency in the coating process.

- Advanced Pretreatment Processes

Automatic Coating employs advanced pretreatment processes tailored to the materials being coated. This includes a six-stage pretreatment for aluminum and a five-stage iron phosphate pretreatment for steel, which significantly improves adhesion and durability.

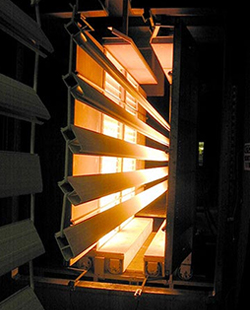

- Fluid Bed Technology

Automated fluid bed systems are also part of their offerings, providing high-quality powder coatings with improved efficiency. This technology allows for consistent application and ensures that the coatings meet the high standards expected by clients.

Unparalleled Turnaround and Reliability

With a focus on automation and efficiency, Automatic Coating boasts an unparalleled turnaround time for projects. Their streamlined processes allow them to manage high volumes while maintaining exceptional quality. Clients can expect reliable service that meets deadlines without sacrificing performance.

In a competitive landscape, choosing Automatic Coating means opting for a partner that embodies innovation, quality, and environmental responsibility. Their comprehensive range of services—from advanced powder and liquid coating to customized fabrication and consulting—ensures that clients receive the best solutions tailored to their needs. With a proven track record in diverse industries and a commitment to excellence, Automatic Coating is the clear choice for businesses looking to protect and enhance their assets. Whether you are in need of pipeline coating services or specialized fabrication, Automatic Coating is equipped to deliver outstanding results every time.

Back