In 2010, Automatic Coating proudly launched its Centre for Pipeline Coating Innovation in Toronto, marking a significant milestone in the fight against pipeline corrosion. As industries increasingly recognize the importance of pipeline integrity, this centre stands at the forefront of research, development, and training, focusing on enhancing pipeline coating processes and providing cutting-edge solutions to the Canadian oil and gas sector.

A Commitment to Innovation

The establishment of the Centre for Pipeline Coating Innovation demonstrates Automatic Coating’s unwavering commitment to advancing pipeline technology. The centre has played a pivotal role in developing innovative systems and processes that address the persistent challenges posed by pipeline corrosion. Corrosion not only affects the lifespan of pipelines but also poses serious environmental and safety risks. By investing in research and development, Automatic Coating aims to create effective solutions that enhance the durability and reliability of pipeline infrastructure.

Key Innovations from the Centre

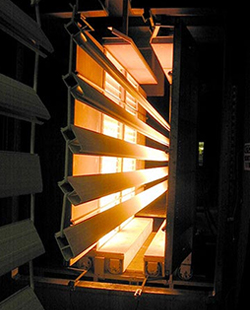

One of the centre’s standout achievements is the development of the Pipe Viper, an automated field blast and coating system designed to streamline the coating process in the field. This system increases efficiency and minimizes human error, ensuring that pipelines receive consistent and high-quality coatings. The Pipe Viper exemplifies how automation can lead to safer, more effective coating applications, ultimately reducing the risk of corrosion-related failures.

Another groundbreaking innovation is the Precision Pipe Coater, which automates the application of shop-applied coatings. This technology enhances precision and reduces waste, making the coating process not only more effective but also environmentally friendly. By adopting such automated systems, Automatic Coating is setting new standards in the industry, prioritizing both performance and sustainability.

The centre also introduced the Pipe Wheelabrator, an automated blasting system that prepares pipes in the shop for coating applications. Proper surface preparation is critical for successful coating adhesion, and the Pipe Wheelabrator ensures that pipes are meticulously cleaned and primed. This tool not only improves the quality of the final product but also speeds up the overall workflow, providing significant time and cost savings.

Finally, the Grawler represents a major advancement in girth weld coating. This automated system ensures that weld joints—often the weakest points in a pipeline—are coated efficiently and effectively. By focusing on these critical areas, Automatic Coating enhances the integrity and longevity of pipelines, helping to prevent leaks and failures.

Training and Certification

In addition to developing cutting-edge technologies, the Centre for Pipeline Coating Innovation prioritizes training and education. Automatic Coating has established a robust training program that equips professionals with the skills necessary to operate advanced coating systems and perform surface preparations effectively. With ten NACE-certified Level One coating inspectors on staff, many of whom are also certified coating applicators, the centre boasts one of the most qualified teams in Canada. This expertise not only benefits Automatic Coating but also elevates industry standards as a whole.

Training at the centre encompasses a range of topics, from surface preparation techniques to the intricacies of different coating materials. This comprehensive approach ensures that participants leave with a deep understanding of the entire coating process, empowering them to implement best practices in their own work environments.

Supporting the Resource Sector

Automatic Coating recognizes the unique challenges faced by the Canadian oil and gas sector. As a critical component of the economy, this sector requires reliable infrastructure to transport resources safely and efficiently. The Centre for Pipeline Coating Innovation is dedicated to supporting this industry by providing innovative, environmentally friendly solutions tailored to meet its specific needs.

The centre is continuously exploring new methods and materials that minimize environmental impact while maximizing performance. This commitment aligns with the broader industry movement towards sustainability, ensuring that the Canadian oil and gas sector can meet its resource demands without compromising environmental integrity.

Looking Ahead

As the Centre for Pipeline Coating Innovation moves forward, its focus remains on innovation and excellence. The challenges posed by pipeline corrosion are not going away; therefore, ongoing research and development are essential. Automatic Coating aims to stay ahead of industry trends by investing in new technologies and exploring alternative materials that enhance the durability of coatings.

Collaboration is also a key aspect of the centre’s future plans. By working closely with industry partners, academic institutions, and research organizations, Automatic Coating seeks to foster an environment of shared knowledge and innovation. This collaborative approach will help drive advancements in pipeline coating technology and ensure that Canada remains at the forefront of pipeline integrity solutions.

Conclusion

The Centre for Pipeline Coating Innovation has established itself as a leader in the field of pipeline corrosion prevention and coating technology. Through its innovative systems, comprehensive training programs, and commitment to supporting the oil and gas sector, Automatic Coating is making significant strides in enhancing pipeline integrity across Canada. As the industry continues to evolve, the centre’s dedication to innovation and sustainability will be crucial in addressing the ongoing challenges of pipeline corrosion and ensuring the safe, efficient transportation of resources.

In an era where environmental responsibility is paramount, Automatic Coating’s Centre for Pipeline Coating Innovation is not just a facility for research and development; it’s a beacon of progress, driving the industry toward a more sustainable and secure future.

Back